Measuring and Inspection Diagnostic Systems

Measuring and Inspection Diagnostic Systems

We provide innovative measuring and inspection solutions tailored to enhance accuracy, improve quality control, and drive operational efficiency across various sectors.

Innovative Advancements in Measuring and Inspection Diagnostic Systems

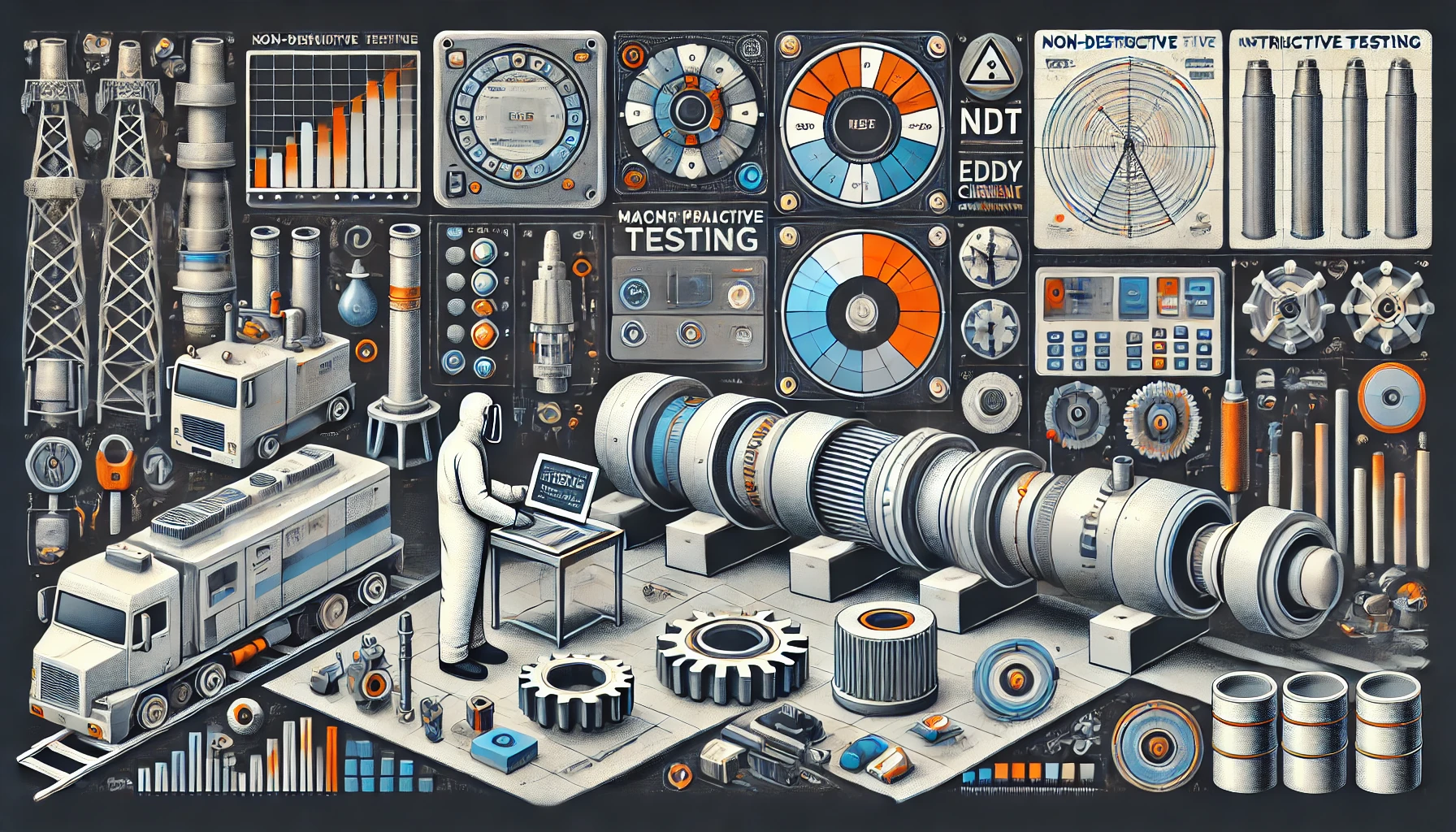

Measuring and inspection diagnostic systems are essential in modern manufacturing and quality assurance, integrating advanced measurement tools, sensors, and data analytics to enhance precision and reliability. From non-destructive testing to automated inspection, these systems drive improvements in product quality and operational performance.

- Seamless integration of measurement tools and quality control processes.

- Improved accuracy through advanced sensor technology and data analytics.

- Real-time monitoring for enhanced quality assurance and compliance.

The shift towards automation and smart manufacturing is transforming traditional measurement practices, utilizing IoT and machine learning to optimize quality control and minimize errors. This transformation not only enhances efficiency but also ensures compliance with industry standards and regulations.

Measuring and inspection diagnostic systems foster a culture of quality and precision in manufacturing. By adopting cutting-edge technologies, industries can meet evolving challenges while ensuring the highest standards of quality. The future lies in continuous innovation, where technology drives smarter, safer, and more efficient production processes.